Aviation And Automation

Aviation And Automation

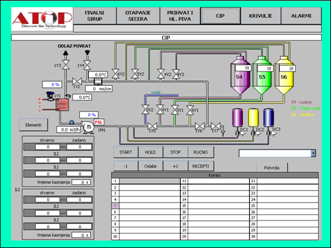

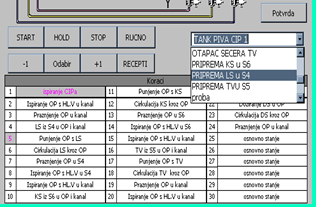

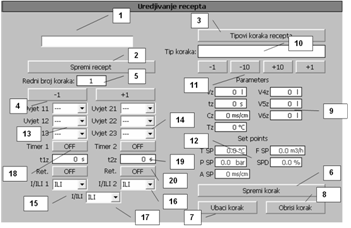

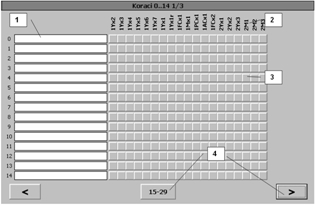

CIP (Cleaning In Place)

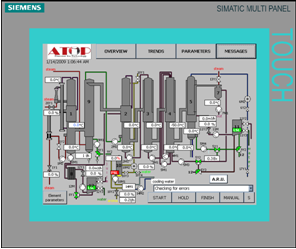

Engineered with Step7 S7315-2DP, HMI WinCC flex panel TP 270 10"

CIP station is used to clean process units in the Food & Beverages, Chemical and Pharma Industries.

In the software we use SFC (sequential function charts) and some PID Loops. Main purpose is to make a flexible and user friendly environment. The operator is able to create own recipes according to the technological requirement. Further the operator can define his own recipe sequence by influencing every process object (motor, valve, control loop) and all other plant parameters and Boolean logic. The number of steps is unlimited and can be easily edited in the Recipe Matrix Editor on the HMI and saved on the MMC card on the HMI panel.

EVAPORATING PLANT

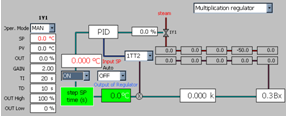

Engineered with Step7 S7315-2DP, HMI WinCC flex panel TP 270 10"

Evaporating plants have a broad application in the food and chemical industry. They are used for evaporating fruit juices, milk, etc. Evaporating plant has 5 evaporation stages through which juice flows, which will be evaporated (to reduce the amount of water) from 20Bx to 64Bx.

In the first stage, juice comes with approximately 20Bx; in this stage, steam also arrives in the system. After that, juice in free fall comes to the bottom of the first stage and then moves on to the top of the second column (stage). The steam from the first stage goes to the second stage. In the second stage, steam temperature is less (temperature profile from the first to the last stage is in levels of 15°C). In total, there are 5 evaporation columns. The main challenge is to control the temperature (with steam-huge time lag) and the flow rate to get the right value of Bx. For example, a temperature change of 1°C on the first stage will change the amount of Bx in about 90 seconds.

Additional product which can be caught in the process of evaporation is aroma. In the second stage, the aroma of juice is evaporating and can be caught with the vacuum system into the aroma tank where it will be cooled down into a fluid state.